Posted: 25/05/18

Engineering innovators showcase their talents

Engineering students at West Nottinghamshire College have been researching and presenting their technical findings at an end-of-year showcase this week.

-

Dame Asha Khemka spoke to Jack Woodcock about an automated label printing system idea

-

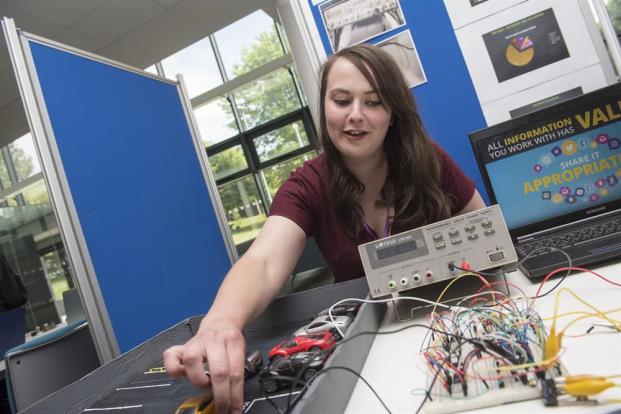

Rebecca Wheatcroft based her project around an intelligent car parking system

-

George Dove and Ryan Worthington, both of Glenair, devised time and energy saving systems for the company

-

HNC Mechanical Engineering student Michael Wilmott looked at the steelwork and carpentry challenges of a garage refit

-

Joe Gent who works for J Tomlinson based his project on a total new electrical system for a refurbished building

-

Jacob Jones worked on a new lighting project for a school building for Derry Building Services where he works

-

Sam Dobson spoke to Steve Burley of Derry Building Services about a system for a garage unit to safely store electronics

More than 30 students presented their final-year projects to tutors, business leaders and fellow students at the fifth Engineering Showcase, on Wednesday (23 May).

The students have each completed either the HNC in electrical and electronic engineering, the HNC in mechanical engineering, or the HND in Electrical and Electronic Engineering, which are part of the college’s range of Higher Education programmes.

Learners work for organisations ranging from Glenair, J Tomlinson Ltd, Rolls Royce, Midlands Aerospace, Synseal to Skanska.

The showcase is designed to help students improve on employability skills, boosting their success in a challenging business environment. By showcasing their projects to a range of sector professionals, including their own employers in some cases, students gain from sharing new ideas, adding to their own learning experience.

Steve Burley, director of Newark-based Derry Building Services, said: “Events like this are enjoyable and very important for both students and employers. I attend each year to look at what young engineers are doing and it’s good to see students developing their skills.

“As chair of the Electrical Contractors’ Association (ECA) National Skills Committee I represent over 3,000 companies across the UK, so it’s great to be able to speak at these events and report back all the new ideas and technologies that I see emerging from trainee engineers, like at West Nottinghamshire College.”

This year, projects ranged from an intelligent car parking system, total refurbishment of a school’s lighting system, a hospital humidity control system and an automated label-printing idea – plus many more innovative projects.

HNC Diploma in Electrical and Electronic Engineering student Rebecca Wheatcroft’s project was based on creating an automated parking system. The 24-year-old, who works for Mansfield building materials supplier, Tool Station, said: “The employer showcase is a great way for us to end the college year and show local employers all our hard work and our new ideas.

“My project was looking at the college car park, based on 70 parking spaces. The idea is to have a barrier in and out which monitors numbers of spaces available so people parking are aware. I’ve used a system called Multisim to design this with the idea of saving users time and patience.”

Joe Gent, who studies on the HNC in Electrical and Electronic Engineering programme, works for J Tomlinson in Nottingham.

Joe said: “My project is based on an electrical refurbishment of an old building in Nottingham. It involves the stripping out, design, supply, installation and test of the entire electrical systems package including lighting, power, fire alarms and security.

“It was quite a challenge but working on this live project at work alongside the college project made it very interesting and worthwhile.”

Ryan Worthington, 20, who studies on the HNC in Mechanical Engineering works at Mansfield-based Glenair Ltd.

He said: “In my department at Glenair, we’ve received a large order for production of a 51-way solder cup connector. The current manual process will not be able to realistically achieve the production quota in time.

“I looked at different types of systems and the one I’ve devised will save a lot of time. It will eventually be a live project running at Glenair and will definitely improve production and lead times.

“Working as an apprentice and having this sort of experience in the job has helped me to replicate it for my college studies - it’s been brilliant.”