Posted: 02/06/16

Engineering excellence showcased to employers

Engineering undergraduates at West Nottinghamshire College have showcased their technical talents to business leaders.

-

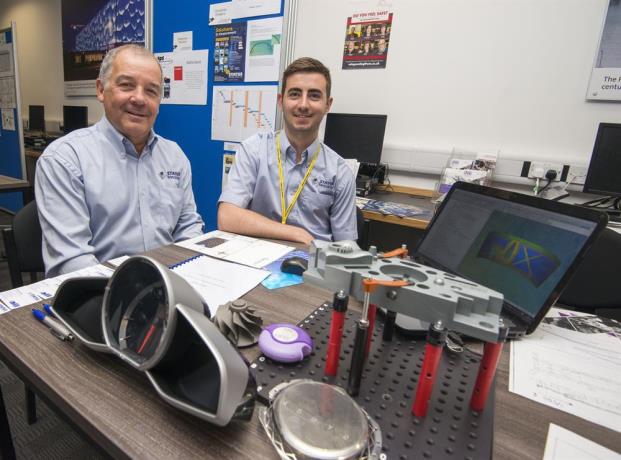

Jonathan Gregory (right) demonstrates his CMM quality inspection system to his employer, Tony Tillett, of Status Metrology Solutions.

-

Tyler Bowen demonstrates his graphics card water-cooling unit to deputy principal Patricia Harman.

-

Daniel Bramley (right) explains his project to produce wing edges for certain types of airbus to Mark Potter of Maun Industries Ltd.

-

Matthew Boardman (right) outlines his proposal to re-design a transmission bearing test rig.

-

Michael Brien with his project to create a report based on the design and build of a solar car port system.

-

Vaidas Perednis presents his lighting design project using software such as Dialux and AutoCAD.

-

Jake Laughton with his environmental project to refurbish Trent Lock, which involved material and design studies.

-

David Pinto (right) explains his project proposal to monitor car parking spaces and regulate traffic flow at college.

-

Mark Stuart with his project – a design proposal to enable a London-based client to clean the windows of its internal atrium.

-

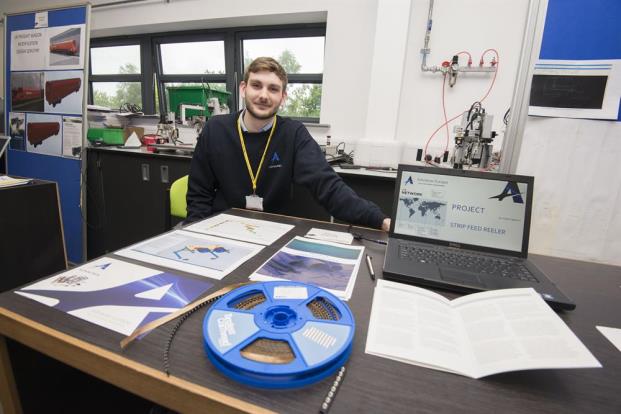

Perry Minett's project was to design, build and implement an ergonomocally-efficient strip-feed reeler.

-

Craig Padmore (left) explains his project to improve an existing tool in his workplace to achieve better results.

-

Engineering tutor Andy Ryan says the showcase "equips students with vital skills and experience for their careers."

Students nearing the completion of their university-level studies presented their final-year projects to employers and tutors at the college’s annual ‘engineering showcase’.

The 33 students have studied either the Higher National Certificate (HNC) in electrical and electronic engineering or the HNC in mechanical engineering, which form part of the college’s higher education provision.

Most are in full-time employment and have studied on day-release after being sponsored by their employer. Projects ranged from new product designs to innovative solutions that could be implemented in the workplace.

Now in its third year, the showcase is aimed at helping students develop the skills needed to make an impact in today’s challenging and competitive business environment. By discussing their projects with industry experts, students benefit from the employer’s perspective who, in turn, contribute to the learning experience.

Employers attending the event – held at the college’s Engineering Innovation Centre in Sutton-in-Ashfield on Wednesday 25 May – included representatives of Axiom Rail, Derry Building Services, Status Metrology Solutions, Advanex Europe, Boneham and Turner, Glenair UK, Maun Industries Ltd, Nottingham Trams Ltd, and SPS Aerostructures.

Following the showcase, students are required to write a reflective report about their project and consider feedback gained from the external visitors.

Mechanical engineering student Jonathan Gregory, who works as a co-ordinate measuring machine (CMM) technician at Status Metrology Solutions, presented his project to his employer, Tony Tillett.

The 23-year-old, from Mansfield, produced a CMM quality inspection system for a customer in the aerospace industry to aid the company’s future manufacturing processes.

Former apprentice Jonathan – who joined the firm five years ago after being recruited by the college’s apprenticeship arm, Vision Apprentices – said: “I think it’s really valuable to show off our skills to employers and other engineers, so they can understand more about what we do.

“It’s also good for my employer to actually see the work I’ve been doing at college, which benefits not only me but the company as well.”

Company director Mr Tillett said: “I’ve kept up-to-date with Jonathan’s progress throughout his course, so it’s nice to see the culmination of all his hard work. From the outset my vision has been to ensure our staff are trained to the highest-possible standard.

“I’ve also enjoyed meeting other students and finding out about their projects too. Everyone I’ve spoken to is really motivated and keen to put what they’ve learnt into practice.”

Electrical and electronic engineering student Tyler Bowen’s project involved designing and building a water-cooled graphics processing unit, which lowers the operating temperature of the device.

The 21-year-old, from Jacksdale, who works as a computer-aided design (CAD) draughtsman at Omega Red Group, said: “I’m really proud of what I’ve produced. Most of it has been done at college, from concept to completion, which meant having the right standard of equipment because it relied on a high degree of accuracy.

“It’s important the college holds events like these and engages with industry. Employers can see what training is being provided and we can also learn from other people’s ideas, so it’s a win-win situation.”

Engineering tutor Andy Ryan, who helped organise the event, said: “The showcase grows in size every year and once again our students have produced some really stunning projects.

“Having this type of format equips students with vital skills and experience for their careers, because industry has changed so much. These days, employees don’t just give presentations in the workplace – they exhibit at jobs fairs and at engineering expos.

“So this event helps them to explain complex engineering projects and processes in simple terms, and have the ability to answer multiple questions, which aids their communication skills.”