Posted: 07/12/15

Bricklayers help to build research of industrial injuries

Bricklaying students at West Nottinghamshire College have been helping researchers from a top London university develop its studies into disorders in the upper limbs of people working in the bricklaying industry.

-

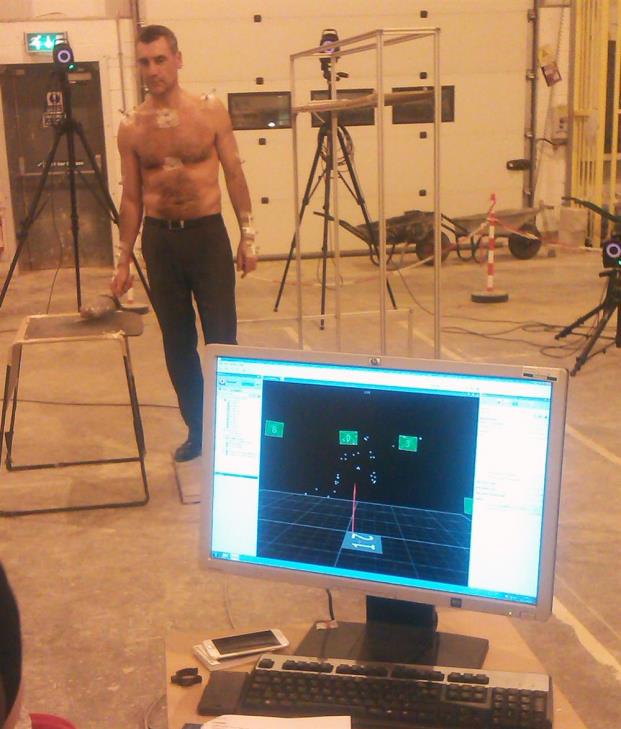

Head of construction and building services Julian Walden takes the test to map his movements while working

-

Research graduate from Imperial College, Sam Smith, is linked to the computer which maps his moves with the trowel

Last week, students and research co-ordinators from the biomechanics laboratory of Imperial College London, visited the bricklaying workshops at the college for three days of hands-on research on students who are entering the construction industry.

The research, which is being led by Professor Anthony MJ Bull, who specialises in the basic mechanics of joints, saw PhD student Haida Ismail join Professor Bull’s research co-ordinator Maximillion Wdowski at the building and construction campus in Kirkby-in-Ashfield as they undertook physical tests on the students.

Students had adhesive reflective markers placed on their hands, arms and torsos which linked to a computer designed to record the movements in the upper body while using the trowel.

Students performed several repetitions of bricklaying motions using their dominant arm to hold the trowel. They were asked to stack four foam blocks, four 2.3kg bricks and four standard 3kg red house bricks on the ground.

The monitoring equipment, which is similar to that used in the making of computer games and film animation, saw infrared cameras picking up the markers on the body, to record every movement as the individual lifted the trowel and bricks.

Haida said: “For my thesis I am examining shoulder and back injuries in both experienced and trainee bricklayers. I’ll be looking to analyse these findings and present them within my research publications and at conferences.

“The students have been really interested in our work and it’s encouraging to think that maybe the results of the research can potentially help in the future in the construction industry, which sees a large amount of industrial injuries every year in the UK.”

Head of construction and building services Julian Walden took part in the physical test as well. He said: “I feel privileged to have been involved in this activity. It’s very important to see that someone is undertaking research on this side of the industry.

“Eventually people working in construction will benefit from this type of research. When I was an apprentice bricklayer, the maximum weight of a bag of cement was 50kg. Now, a safe load has been reduced to 25kg. Through projects like this, it will change the way the trade works and will help to protect workers in the future.”