The engineer falls silent as the submarine’s lights flicker off. The only sounds remaining are the hum of instruments and the faint crackle of the intercom. Outside the porthole: a vast, impenetrable blackness, followed by a slow cascade of pale particles, floating like forgotten dust. Ahead, concealed in the darkness, a laser-guided drill is slowly carving into the seabed, tracing a precise arc beneath two continents that have never been closer.

On the support ship above, screens light up with live data from the ocean floor: pressure, temperature, micro-tremors. The coffee cups on the table tremble slightly with each wave that hits the hull. A young project manager leans forward, realizing that the flickering line on the sonar isn’t a fish or a cable, but the first signs of a future rail line, one that will allow passengers to cross an ocean without ever leaving the ground. It feels almost like a dream.

But the work is real. Steel rings, robotic drilling heads, fiber sensors. What sounds like science fiction is now becoming a tangible project, with real engineering budgets. Between fear and fascination, a new era is being drilled into the depths of the ocean.

The Deep-Sea Tunnel That’s Redefining Geography

When people think of underwater tunnels, they usually mention the Channel Tunnel or perhaps the Bosphorus Rail Tunnel, if they follow infrastructure news. Few realize that engineers are already working on something far bolder: a deep-sea rail tunnel that will stretch under thousands of meters of water, connecting two continents in a single, steel‑lined, pressurized sweep.

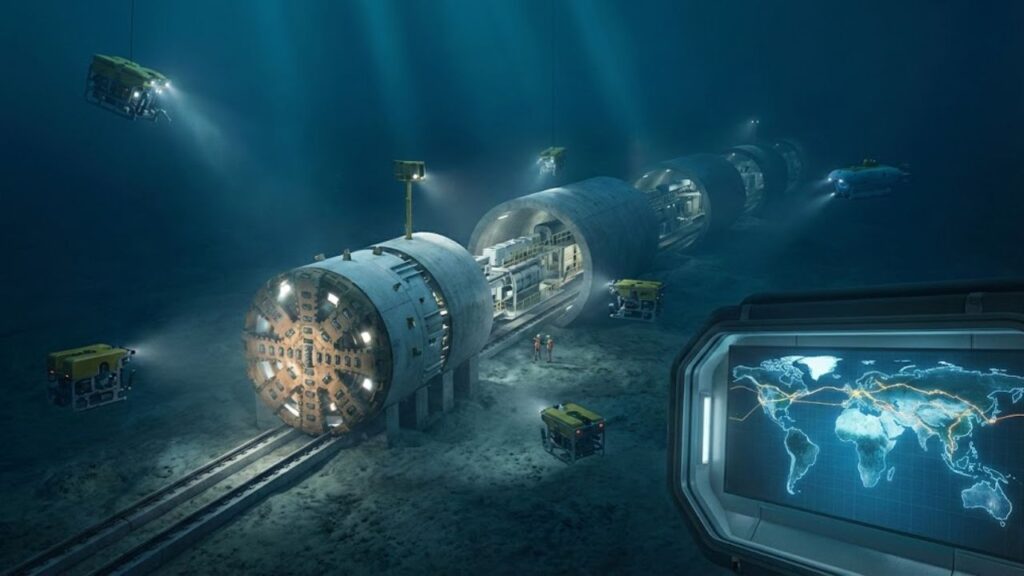

This isn’t a futuristic concept or a viral render. It’s a real construction site. Survey vessels have been mapping the seabed for months using advanced sonar. Test modules have been deployed to simulate pressures that could crush a car like a soda can. Robotic crawlers inch along the ocean floor, checking sediment layers and fault lines. The tunnel’s exact alignment changes millimeter by millimeter, as the data comes in—almost like a slow, deliberate negotiation with the Earth itself.

To grasp the scale of this, forget subway lines and think instead of a buried spaceship hull. The planned rail tube must survive the corrosive saltwater, extreme pressure, and constant movements of the Earth’s crust. Engineers speak not in architectural terms, but in medical ones: “tunnel health,” “fatigue cycles,” and “failure prevention.” Each joint, each gasket, each concrete segment is tested millions of times before being used. The tunnel is not simply dug; it’s engineered to survive decades of invisible forces.

What makes this tunnel different from past projects is the depth. While the Channel Tunnel runs through relatively shallow seabeds, this new corridor plunges into waters usually reserved for telecom cables and deep-sea creatures. Engineers are blending methods from mining, offshore oil rigs, and high-speed rail. They’re creating a space where passengers can travel in comfort, while outside the walls, the ocean presses in with a force no human body could withstand. It’s a calm ride inside, with the ever-present, silent pressure of the deep ocean outside.

A Deep Dive into the Human Side of Engineering

Some of the engineers and project managers have followed this tunnel from initial design to the ship’s deck, moving between continents before the tunnel does. They describe the strange disconnect: working on a vessel in the middle of nowhere, constructing a path that will make “middle of nowhere” feel obsolete. For many, the first time they ride the completed train, they’ll likely be overwhelmed by the full scope of what they’ve created.

From an engineering perspective, the logic is clear. Air travel is fast but carbon-intensive. Shipping is cheaper, but slower. Traditional tunnels are effective but limited by coastal geography. A deep-sea rail link offers a middle path: long journeys without check-in lines and freight routes free of detours. The idea is deceptively simple: draw a straight line under the ocean and then make reality bend to it.

How to Build a Train Line Beneath an Abyss

On the surface, the method might seem straightforward. Huge precast tunnel segments, like giant Lego bricks the size of apartment buildings, are built in dry docks along the coast. Each segment is sealed with temporary bulkheads, floated out to sea, and guided into position by tugboats. Once there, it’s slowly sunk to the seabed and joined with precision that would impress a watchmaker. Inside these segments, rails, cables, ventilation ducts, and evacuation passages are added, creating a complex, multi-layered structure. Engineers call it an “immersed tube” system, but that term doesn’t fully capture the complexity: the challenge is aligning these segments perfectly across hundreds of kilometers, all while the ocean tries its best to distort, warp, and corrode every exposed edge.

Unlike what many people imagine, this tunnel is not a static pipe. Engineers talk about it like a living organism. Expansion joints must flex with temperature differences between the deep ocean and the terminals. Drainage systems must handle water infiltration that nobody will ever see. Emergency exits and pressure-safe cross passages are placed strategically, considering not just regulations, but the actual panic distances on a crowded train in distress. These aren’t the tasks most of us deal with every day.

Lessons learned from older megaprojects have shaped the design process, avoiding delays and budget overruns. What happens if an autonomous repair robot fails deep underwater? What if a minor earthquake shifts a segment by a few millimeters? What if political changes disrupt funding halfway through construction? Teams now factor in “resilience margins”—extra capacity in pumps, spare ducts, more sensors than strictly necessary. The line between “over-engineered” and “future-proof” is thin, and they intentionally walk it.

Turning Fear into Design Strategy

We’ve all been there: that moment when a grand promise sounds too smooth, too perfect, and your mind whispers, “What could go wrong?” Engineers on this project ask themselves that question every day. They’ve turned that fear into a design tool rather than a mood. As one senior geotechnical expert put it:

“The ocean doesn’t care about your schedule or your press release. It just cares whether the physics work. Our job is to earn its indifference.”

This attitude permeates their work, from checklists to protocols. Crews run drills for:

- Sudden seabed shifts during segment placement

- System-wide sensor failure during a storm

- Micro-leaks discovered years after installation

- Evacuations in a pressurized, sealed environment

Every scenario is meticulously rehearsed. It’s all about preparation—slow, meticulous, and stubbornly thorough.

How a Deep-Sea Tunnel Will Become Part of Our Daily Lives

The strangest part of this story is that if the project succeeds, most of us will barely notice. We’ll book tickets because it’s cheaper than flying, or because the check-in process is smoother. We’ll roll our luggage onto the train, glance at the departure board, and then settle into our seats, barely registering the fact that we’re under an ocean. By the time we remember, we’ll be two playlists deep into our journey.

This is how great infrastructure often unfolds: quietly, in the background of daily life. People will commute weekly across continents, complaining about the Wi-Fi or the coffee. Families will enjoy panoramic views in the lounge car, watching sea life on screens as they travel. Freight operators will simply input the new route into their software. And the engineering marvel will be reduced to passing conversations about delays or seat comfort.

Yet, beneath the sonar scans, spreadsheets, and corrosion-resistant bolts, there’s a subtle shift in how we view the planet. Continents, once separated by hostile waters, begin to feel like neighborhoods separated by a long tunnel walk. For some, it will be a symbol of reduced emissions and global travel reimagined. For others, the allure will be the raw curiosity of crossing an ocean in a man-made tunnel, trusting in thousands of invisible calculations.

There are no guarantees this project will meet every timeline or budget. No megaproject does. But the work is already underway, and that alone pulls this idea from fantasy into reality. The next time you trace your finger across the map, you might feel a subtle jolt of recognition. Somewhere beneath the waves, a line is already being carved: a path that says, “cross here.”

| Key point | Detail | Value for the reader |

|---|---|---|

| Deep-sea rail tunnel under construction | Engineers are actively surveying, assembling and placing immersed tube segments between continents | Helps you separate concrete progress from sci‑fi buzz and understand what’s really happening |

| Hybrid methods from multiple industries | Techniques from mining, offshore platforms and high-speed rail merged into one project | Gives context on why this tunnel is different from classic links like the Channel Tunnel |

| Future travel and logistics impact | Potential for faster, lower‑carbon intercontinental trips and more direct freight routes | Lets you imagine how your own journeys and the global economy could shift |