In the rolling hills between Lyon and Saint-Étienne, engineers are quietly developing an all-electric aircraft that looks nothing like today’s regional planes. Designed to consume only a fraction of the energy used by conventional jets, it aims to connect small towns, lakes, islands, and remote valleys without burning a single drop of kerosene.

A bold response to aviation’s rising climate challenge

While aviation still accounts for a modest share of global emissions, its climate footprint is increasing rapidly as flight numbers grow and long-distance routes expand. Governments and manufacturers are placing heavy bets on sustainable aviation fuels (SAF), which can be used in existing aircraft and airport systems.

Alongside this approach, a more disruptive idea is gaining traction: aircraft that need far less energy from the start. French startup Eenuee is firmly aligned with this second path.

Gen-ee and the promise of ultra-low energy flight

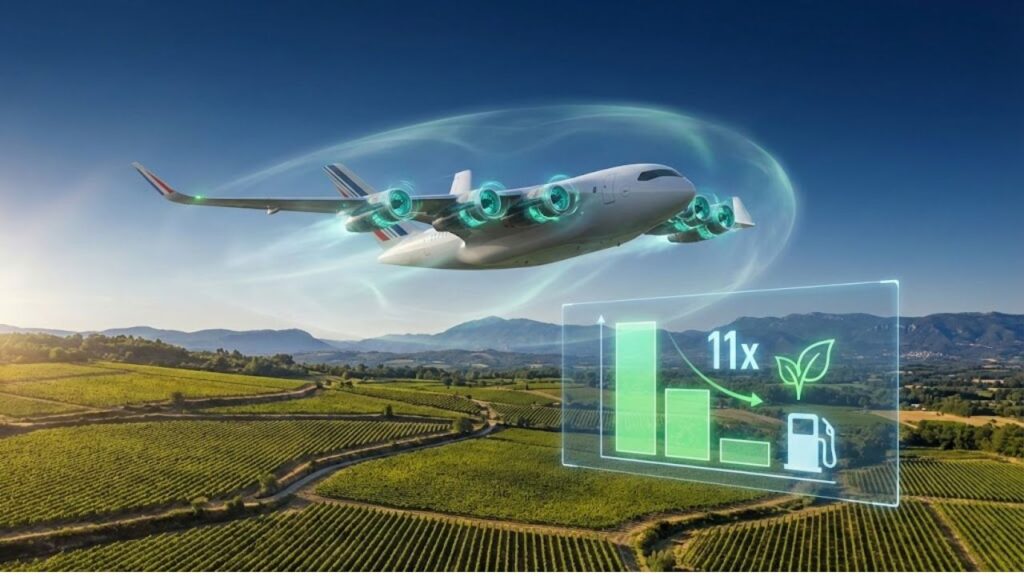

Eenuee’s Gen-ee regional aircraft is designed to consume up to 11 times less energy per passenger-kilometre than comparable planes flying today. If achieved, this would dramatically alter the economics of short-haul aviation and challenge the assumption that only rail can offer clean regional mobility.

Introducing Gen-ee: a 19-seat electric regional aircraft

Founded in 2019 in the Rhône-Alps region, Eenuee is developing Gen-ee as a fully electric aircraft optimised for short regional routes. Its specifications are intentionally restrained:

- Up to 19 passengers

- Approximately 500 km (310 miles) of range on batteries

- Maximum take-off weight of around 5.6 tonnes

- Planned certification under the CS-23 light aircraft category

This aircraft is not meant for transcontinental journeys. Instead, it targets underserved routes between small cities, mountainous areas, islands, and remote regions where traditional airlines have withdrawn due to poor profitability.

Industrial partnerships anchoring the concept

Gen-ee is being developed in collaboration with Duqueine Group, a composites specialist and long-time supplier to major aerospace companies. This partnership grounds the ambitious design in proven industrial expertise and certification experience, two factors often missing from futuristic “flying car” concepts that never leave the drawing board.

An aircraft design that defies first impressions

A lifting fuselage replaces the classic tube

Most passenger aircraft follow the same formula: a cylindrical fuselage, wings attached on either side, and a tail for stability. Gen-ee breaks this mold by adopting a blended wing body, where the fuselage itself contributes to lift.

The smooth transition between wings and body allows the entire structure to generate lift while reducing drag. Although studied for decades by NASA and Airbus, this architecture remains rare in commercial aviation due to its design and certification complexity.

Flight control without a traditional tail

Gen-ee eliminates the conventional tailplane used for pitch control. Instead, it relies on elevons along the trailing edge of the wing-fuselage, similar to those found on certain military aircraft. While this increases control system complexity, it enables significantly higher aerodynamic efficiency.

Targeting a glide ratio of 25

Eenuee aims for an aerodynamic glide ratio of around 25. For a regional aircraft, this is an ambitious goal, meaning the plane could travel roughly 25 metres forward for every metre of altitude lost in clean conditions.

A higher glide ratio translates into lower thrust requirements, reduced battery drain, and the option to carry lighter battery packs for the same mission profile.

Three pillars behind the “11 times less energy” claim

According to Eenuee’s engineers, three core design choices underpin Gen-ee’s dramatic energy savings:

- Advanced aerodynamics through a blended wing body that reduces drag

- Electric propulsion using battery-powered motors with efficiency approaching 90%

- Lower structural weight achieved with carbon composites and a non-pressurised cabin

Eliminating cabin pressurisation significantly reduces structural mass and maintenance demands, as there is no pressure vessel subjected to repeated stress cycles. The trade-off is lower cruising altitude, typically below 10,000 feet, which aligns well with short regional flights.

From runways to lakes: a multi-surface aircraft

Gen-ee is being designed to operate beyond traditional runways. Eenuee is developing a version capable of water take-offs and landings using hydrofoils, small underwater wings that lift the aircraft clear of the surface as speed increases.

At higher speeds, hydrofoils dramatically reduce water drag, enabling short take-off runs on lakes and rivers. Unlike conventional floatplanes, this variant remains fully amphibious, allowing seamless operation from both water and land without hardware changes.

Opening new markets for scattered communities

This flexibility could unlock new routes in archipelagos, fjord regions, and lake-rich territories. Regions highlighted by the company include parts of Asia, Scandinavia, and Canada, where dispersed populations and extensive waterways make air connections valuable but traditionally costly and polluting.

What Gen-ee could mean for remote regions

A major advantage of Gen-ee lies in what it does not require. The aircraft can operate from existing small airfields without long runways or major infrastructure upgrades.

Ground facilities would be relatively simple: covered passenger areas, basic maintenance spaces, and electric charging stations similar in concept to those used for electric vehicles. This appeals to regional authorities seeking better connectivity without investing in new airports or high-speed rail.

Materials, weight, and the certification challenge

To meet its performance targets, Eenuee is relying heavily on carbon-fibre composites and high-performance aluminium alloys. Composites offer an exceptional strength-to-weight ratio and allow the complex curves required for a blended wing body.

Every kilogram saved at the design stage reduces battery size, motor loads, landing gear demands, and energy consumption across the aircraft’s entire lifespan.

Progress toward European certification

Eenuee is working toward CS-23 certification, which applies to aircraft with up to 19 seats and a maximum take-off weight of 8.6 tonnes. Current testing uses 1:7 scale demonstrators, with a 1:4 model planned to address manufacturing and flight-control challenges.

The company aims to identify aerodynamic risks and failure modes early, well before committing to a full-scale prototype. Formal certification efforts and Design Organisation Approval are expected around 2027, with a first flight targeted for 2029.

Electric aviation without massive infrastructure

A common concern around electric flight is infrastructure demand. For small regional aircraft like Gen-ee, requirements are more manageable.

Charging systems are envisioned to resemble those already deployed for electric road vehicles and ground equipment. Many small airfields could begin with a limited number of high-power chargers and schedule flights around charging windows, avoiding costly hydrogen or SAF facilities in the early stages.

Potential future roles beyond passenger travel

If Gen-ee performs as intended, its lifting-fuselage concept could be adapted to other missions. Eenuee points to medical evacuation, humanitarian aid, light cargo, and defence applications as potential extensions.

The aerodynamic benefits scale across sizes, allowing future variants to carry more passengers, additional cargo, or extra battery capacity without abandoning the core design principles.

Rethinking the passenger experience

For travellers, Gen-ee would feel different from today’s regional jets. The wide, wing-shaped fuselage allows for new cabin layouts, including more open seating, panoramic windows near the leading edge, or modular interiors for stretchers and bulky freight.

Noise levels are also expected to drop, thanks to electric motors and the absence of a pressurised shell, reducing vibration and structural noise.

Understanding energy efficiency and lifecycle impact

Two core ideas underpin projects like Gen-ee: energy efficiency and lifecycle impact. When Eenuee refers to “11 times less energy,” it means the total energy required to move each passenger over a given distance, factoring in aerodynamics, weight, and propulsion losses.

Even if electricity initially comes partly from fossil sources, using far less energy per seat makes decarbonisation easier as power grids grow cleaner.

Beyond operational emissions, lighter structures and smaller batteries also reduce the environmental burden of manufacturing and recycling. Across thousands of regional flights each year, the cumulative impact could rival or exceed the gains promised by liquid biofuels alone.